Plasma enables UV metal printing

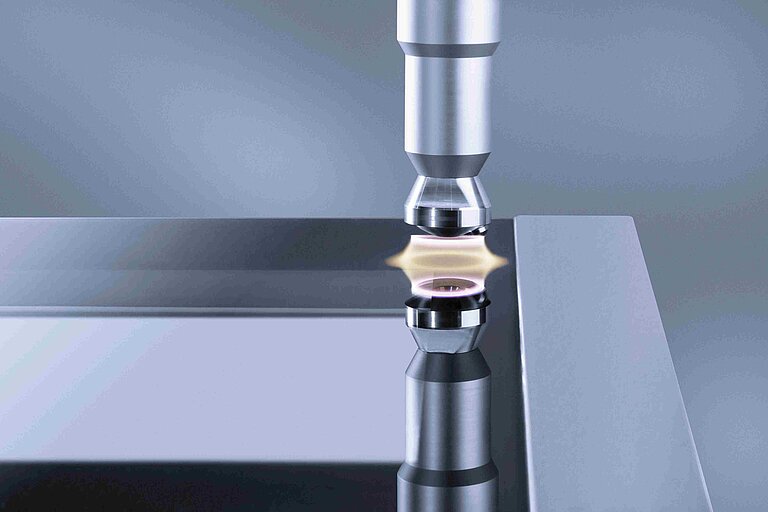

A completely new, patented atmospheric plasma source enables intensive, metal-specific surface treatment, resulting in a flawless surface that is virtually free of organic contaminants. This preparation of the surface for printing achieves unprecedented adhesion for UV inks, allowing them to withstand subsequent production steps such as deep drawing and flanging without problems. Unlike previous pretreatment processes, which use solvents and require a lot of energy and ovens, the new process works without solvents. The curing time of the UV-based inks is less time and energy consuming, and the performance now achieved also enables high production speeds of up to 6500 metal sheets per hour.

By using nitrogen and its strong ionization in the plasma source, high kinetic energy is transferred to the material to dissolve the organic contamination from the metal surface. This unique treatment is similar to high intensity annealing, but in this case the temperature exposure is very short and therefore more favorable to the material.

How Does this Exactly Work?

Like no other form of energy, plasma energy is outstandingly suited for targeted surface treatment of all types of materials. Even highly sensitive surfaces can be reliably and safely cleaned, activated and coated. This creates microfine, pure metal surfaces that enable uncomplicated wetting and adhesion of the UV coatings and/or printing inks.

Plasmatreat Live METPACK 2023

Openair-Plasma® - Making Surface Treatment Sustainable

At this year's METPACK we will present our Openair-Plasma® technology for the application in the metal packaging industry for the first time at booth 3C55 in hall 3. Working closely with our partners Brasilata and Actega, we have managed to integrate atmospheric plasma technology into an existing production line at Brasilata, making the use of UV coatings on steel (TP/TFS) viable for the first time.

Let our project team explain to you on site the development process and the application of plasma technology in this special case and show you how the use of a plasma system can open new ways also in your production.

In addition, we will give you a compact introduction to atmospheric plasma technology. We will show you our Openair-Plasma® live on site and explain what makes plasma application an efficient and environmentally friendly alternative to conventional surface treatments of metals.

Atmospheric plasma technology is a "game changer" when it comes to adhesion properties, substrate replacement or functionalization of surfaces. Make an appointment right now and stop by to learn more about Openair-Plasma® technology.

Let's meet live at METPACK 2023

Comprehensible demonstration on modern plasma system for flat materials

Visitors at METPACK can discover the plasma prozess live: A plasma system that pretreats flat substrates prior to printing with UV inks or coatings will be presented. This system has eight rotating nozzles and will treat materials, such as metal sheets for can production, before printing or painting. With the rotating nozzles, a large-area of the metal surface is pretreated with plasma uniformly. Precisely matching the speed, the distance between the nozzle heads and the substrate, and the intensity of the plasma nozzle to the application in question is one of Plasmatreat's core competencies. The innovative system for this patented process can be excellently integrated into existing lines.

Ticket Raffle

Are you interested in learning more about Openair-Plasma® in metal packaging processes? Would you like to visit us at METPACK 2023 from May 2nd - 6th, 2023 in Essen and get to know Plasmatreat?

Then here is your chance to win your entrance ticket with us. Participate now and let us discuss your processes and find an optimal and sustainable solution together.

By sending the button you automatically accept the conditions of participation.

Take your chance now and win your ticket for METPACK 2023!

We are Ready for Your Challenge

With our global sales, service and partner network we are able to support you - wherever you are. With our expertise and experience we are well prepared to help you with your demands in the area of specialized surface treatment.

You have more questions that need detailed explanation? Book your appointment now live at the METPACK 2023 or use our contact form to get in contact with our surface treatment experts directly.