Offcanvas Navigation

Extruded Profiles and Pipes Without Adhesion Problems

Surface quality is crucial for meeting the high standards required for end products, such as EPDM door or window profiles. To ensure consistent high quality and reliable processing, the profiles must be pretreated before the individual manufacturing steps. One effective method is treating the material surface with atmospheric pressure plasma.

Would you like to test plasma for your product?

Win a Material Test at Plasmatreat

Openair-Plasma® solves your challenges in material pretreatment and manufacturing EPDM profiles, window profiles, and pipes. Whether you need to improve adhesion before printing or bonding, for subsequent anti-friction coating, flocking, tape application, or 2K extrusion, plasma can solve your adhesion problems and make your production more sustainable and efficient, even with the most difficult materials.

Are you interested in learning more?

Your Efficient, Cost-effective Solution for Perfectly Adhering Profile Surfaces: PLASMA.

Your Advantages with Openair-Plasma®: It Is an Innovative Alternative to Conventional Pretreatment Methods.

This Cost-effective, Inline-compatible, Low-maintenance Method Is Ideal for Your Needs. It Only Requires Compressed Air and Electricity.

EPDM Door Profiles

- Higher adhesive strength: Plasma activation ensures reliable adhesion of coatings, flockings, tapes, and 2K extrusions without contact.

- Gentle treatment: Contactless activation replaces grinding or brushing. This protects the elasticity of the EPDM and prevents material abrasion.

- Inline efficiency: Seamless integration into the extrusion line reduces production steps and waste.

Window Profiles

- Reliable adhesion: Plasma ensures uniform surface activation for two-component extrusion, film lamination, painting, and bonding, even with different material combinations.

- Selective pretreatment: Choose full-surface or selective activation depending on the subsequent process step without damaging the profiles.

- Process optimization: In-line application saves time, increases reproducibility, and reduces waste.

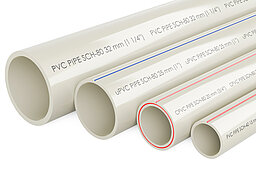

Plastic Pipes

- Optimal printability: Plasma improves surface energy, ensuring permanent adhesion of markings.

- Environmentally friendly adhesion promotion: Achieve activation and sealing without the use of chemical additives.

- Gentle surface activation: Contactless and selective to reduce material abrasion and waste.

Watch Plasma Technology Firsthand. Its Various Applications Offer Countless Possibilities.

At the Plasmatreat booth, technology becomes an experience.

Various exhibits and areas demonstrate how atmospheric pressure plasma can transform your production processes.

In Hall 11 at Booth I65 You Will Get Exciting Insights

Durable Profiles and Pipes—Plasma is The Solution for Perfect Adhesion

Adhesion problems during various production steps are a well-known issue in extrusion, whether with plastic pipes, window profiles, EPDM seals, or hybrid materials. At K 2025, see how our EDM system with Openair Plasma® reliably activates even the most challenging surfaces for optimal adhesion. Plasmatreat is setting new standards in profile and pipe extrusion with its modified system.

Plasma is applied precisely where needed—inline, contact-free, and fully automated. The system offers maximum process stability and enables VOC-free applications while reducing scrap, material costs, and rework. Thanks to its modular design, the EDPM system can be adapted to your specific production needs.

Advantages for your production:

- Ensure optimal adhesion: It provides perfect preparation for printing, bonding, flocking, or coating, even with complex profile geometries and difficult materials.

- Inline, modular, and flexible: Seamlessly integrates into any extrusion line. We offer everything from cost-effective standard solutions to customized, high-end systems with optional process control and quality assurance.

- Chemical-free and sustainable: No VOCs, solvents, or mechanical abrasion—just air, electricity produce plasma. It is environmentally friendly and safe for people and materials.

- Reproducible results: Precise control of the plasma nozzles enables consistent adhesion values, reducing scrap and rework.

Improving Performance With Plasma

Whether in Manufacturing or Sports

Golf balls, skis, paddle rackets, bikes, and Frisbees may seem ordinary at first glance. However, this is precisely where the difference between average durability and top performance begins.

Many products designed for performance lose their quality faster than their price suggests and faster than users would like. Peeling paint, cracked surfaces, and weakening material bonds are often invisible and only discovered at a late stage.

At the Plasmatreat booth, you can see how innovative pretreatment makes a difference. Openair-Plasma® optimizes material properties for a wide variety of sports, including golf, skiing, road cycling, paddle sports, and Frisbee, to achieve the best possible surface structure and adhesion, even for protective coatings.

PUR In-mold Coating

Plasma Revolutionizes Pretreatment

See how the latest plasma nozzle technology is used to pretreat the entire surface of large components, such as dashboards. Imagine your components being treated with Openair-Plasma® immediately after injection molding, creating the perfect foundation for subsequent PUR in-mold coating. Unlike flame treatment, masking is unnecessary. The process is precise and selective and can be used over large areas. It also scores points for its excellent reproducibility.

Plasma technology only requires compressed air and electricity, eliminating the need for expensive gas and CO₂-intensive processes. You benefit from higher quality, lower costs, and sustainable production.

Experience the live plasma treatment of dashboards, hoods, and sunroofs in Hall 11, Booth I65.

Strong Partners – Strong Solutions

Our technology is used worldwide in cooperation with leading manufacturers

Participate Now and Visit Plasmatreat at Booth, I65, in Hall 11 for Your Chance to Win. We are giving away one grand prize and six additional prizes to all participants.

1st Prize:

An Exclusive Material Test

Experience our technology up close. See firsthand how our surface treatment can make your production more sustainable, efficient, and economical.

- Send in your material

- Spend a day in our application technology department

- Test your components with Openair-Plasma®, PlasmaPlus®, or HydroPlasma®

2nd-7th Prize:

A Three-pack of Smart Golf Balls Pack Or a Plasma-treated and Personalized Printed Power Bank

Win three trackable golf balls — for less plastic waste and more golfing fun! With the kind support of our partner Chip-Ing Ltd.

Or keep you and your electronic devices ready for action with your new personalized power bank.

- Track you golf ball via app and view performance data

- Play longer and more sustainably

Can't Make It To The Trade Fair?

No problem! You can still secure your chance to win. We are giving away three additional trackable golf balls to all online participants.

Simply fill out the contact form to be automatically entered into the prize drawing.